How to Measure a Box: Practical Tips for Accurate Results in 2025

Understanding Box Measurements

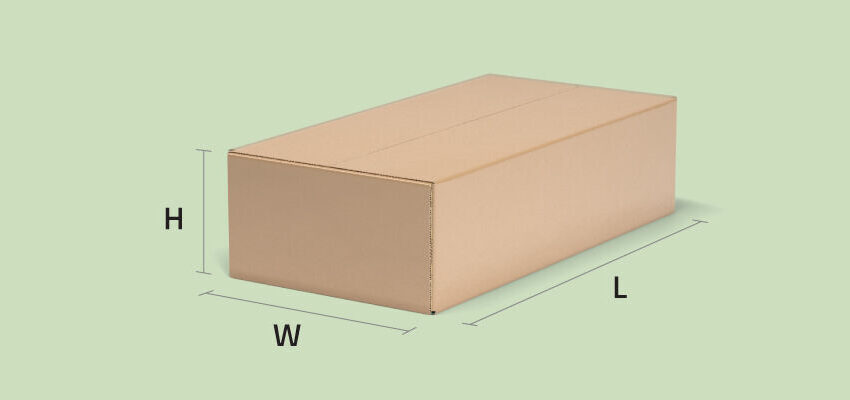

When it comes to shipping or storing items, knowing **how to measure a box** correctly is essential. Measurements of boxes provide guidance for packaging and shipping, ensuring that the container fits both its contents and the designated space. Proper box measurement techniques typically entail calculating the **box length, width, and height**, which are critical dimensions to ascertain whenever you assess any box dimensions. Accurate box measurement affects various factors including shipping costs, storage efficiency, and packaging material requirements. In 2025, staying updated with the latest box measuring methods will ensure that you achieve the most meticulous results possible.

Box Before Measuring: Key Measurements Explained

To effectively measure your box, you should understand the significance of each key measurement: **box length**, **box width**, and **box height**. The **box length** is the longest side, while **box width** refers to the edge perpendicular to length, and **box height** is the distance from the base to the top. When measuring, use a **measuring tape for boxes** for precision. This tape can help maintain consistent results, reducing discrepancies that often arise with other measuring tools like rulers. To measure accurately, ensure the box is placed on a flat surface and check the **dimensions of a box** individually by measuring **box corners** from and to each position.

Box Measurement Techniques

Depending on the nature of your box, there are various **box measuring techniques** to ensure comprehensive understanding and measurement accuracy. A practical method includes using **DIY box measuring** techniques, where you simply employ typical household measuring tools such as a meter stick or measuring tape. For cartons, ensure to measure both external vs. internal values to account for the thickness of materials. Understanding how to calculate **box volume** is equally crucial, typically illustrated as Volume = Length x Width x Height, which assists in confirming that your chosen box can comfortably enclose your items.

Best Practices for Measuring Boxes

What are the best practices for accurate box measurement? Start by clearly defining each dimension and paying special attention to any inclinations or irregular shapes. Be sure to double-check any measurement with a ruler and take notes of all dimensions to avoid **measurement discrepancies**. Furthermore, using **box calculators** or apps can streamline the process, letting you focus on getting ***precise box dimensions***. As you measure, consider how these dimensions relate to your box’s purpose – whether it’s to hold fragile items or to maximize shipping space.

Tools and Equipment for Box Measurements

The right tools are necessary for ensuring effective box measurement solutions. Box measurement tools are not limited to just standard measuring tapes but can also include more advanced equipment tailored for various applications. Using the appropriate tools will guarantee more precise readings and enable quicker measurements without the hassle of errors or added complexity.

Box Measuring Tools: An Overview

Various **box measuring tools** can be utilized deserving of mention. Of course, **measuring tape for boxes** remains a favored choice for its ease of use and practicality. For significant volume calculations, **box measurement calculators** can assist in weighing variables and producing results with minimal effort. Online box measurement apps are also emerging as useful resources, providing **box specifications** on demand and enabling users to check their measurements anytime.

Custom Solutions: Box Measurement Equipment

For businesses or environments involving frequent measurement of boxes, investing in specialized box measurement equipment may become invaluable. Automated systems can allow businesses to measure dimensions quickly, providing precise data for operational efficiency. Incorporating technologies that integrate machine learning with manual measurements improves the overall accuracy of **understanding box measurements** and gives companies a competitive edge in handling logistics efficiently. Employing such intelligent solutions can save labor costs and reduce errors in the packaging process.

Measuring Irregular Boxes

While most boxes have regular dimensions, some boxes are uneven or irregularly shaped. **Measuring irregular boxes** involves utilizing flexible measuring tapes that can wrap around various contours of the box. You might also consider digital measuring scales to precisely assess variations. Accurately capturing **external vs. internal box measurements** assists in determining the exact capacity and ensuring contents receive adequate protection during transport. Adopting a methodology that accommodates precise measurements – even for unconventional styles – should remain a priority for adaptive packaging solutions in 2025.

Guidelines for Box Size Determination

Learning how to accurately define box size and determine effective measurements adheres to packaging guidelines essential for successful shipping and storage. Knowing the metrics can help users adhere to shipping restrictions while still ensuring utility and functionality. Proper box size determination leads to better inventory management and can enhance product presentation to consumers. By applying measurement standards, you ensure that you are one step closer to maximizing efficiency in logistics.

Box Measurement Standards

In terms of **standardized box measurements**, awareness of packaging standards formulates a foundational principle for any shipping-related endeavor. Guidelines dictate both internal and external measurements, with margin preferences typically established based on container design. Implementing these **packaging standards for boxes** can streamline the shipping process while providing useful insights applicable across business models. As an example, consider the standard **dimensions of a shipping box** as a benchmark for rapid comparison when checking competent alternatives.

Practical Case Study: Effective Box Size Calculations

Consider a real-world scenario where a business needs to measure boxes for maximum shipping efficiency. Such a business must determine the precise box capacity to optimize shipping routes based on weight limits. A systematic breakdown by measuring box volume calculations, storage capacities, and shipping requirements is necessary. Using a structured approach, tools for measuring boxes help settle distinctions while holding tight to proper **box measurement standards**. Continually revisiting box dimensions during product cycles aids even in improving logistics based on evolving design and user considerations.

Environmental Considerations and Measurement Practices

Ultimately, being policy aware of **environmental considerations in box measurements** translates to improved resource utilization via fewer boxes or lighter materials. Companies can minimize logistical waste through the proper assembly and measurement guidelines. This creates renewed missions concerning sustainability and eco-conscious operations, whereby every **box measurement** resonates with positive business ethics leading towards greener practices in shipping and packaging.

Key Takeaways

- Understanding **how to measure a box** correctly is essential for efficient shipping and storage.

- Utilizing proper **box measuring tools** enhances accuracy, significantly improving logistics practices.

- When dealing with irregularly shaped containers, consider flexible measuring methodologies.

- Environmental considerations are pivotal for sustainable operations in the packaging industry.

- Employ structured strategies while calculating box volume to meet shipping requirements effectively.

FAQ

1. How do I use a measuring tape for box measurements?

Using a **measuring tape for boxes** involves initially laying the tape flat against the box. Measure from the base to the top edge to obtain the height, then measure across the length and width. It’s vital to ensure the tape remains tight against the box surface while avoiding any curves, enhancing measurement accuracy.

2. What are common **box measurement discrepancies**, and how can they be avoided?

Common discrepancies arise from misalignment while measuring or confusion between **external vs. internal box measurements**. To avoid these, always double-check measurements using multiple tools, and emphasize clarity in definition before beginning measurements.

3. What is the best way to measure small boxes accurately?

For small boxes, using precise **box measuring tools** like a caliper or agreeing to the classic **measuring tape techniques** will yield immediate accuracy. Employing these straightforward solutions eliminates doubts, assisting in producing reliable measurements even in tighter confines.

4. Why is it crucial to measure for packaging standards?

Measurement for packaging standards is vital to prevent shipping errors and reduce costs associated with non-compliance. Adherence to specified **packaging standards for boxes** ensures ease in systematic distribution and promotes smooth shipping practices.

5. How can I calculate box capacity efficiently?

To calculate **how to measure box capacity**, apply the formula Volume = Length x Width x Height. This measurement will offer critical information about what items fit within the box, leading to advised shipping practices and box usage. Ensure all numbers are in consistent measurement units to achieve uniformity.